What product types are included in stainless steel resistors?

What Product Types are Included in Stainless Steel Resistors?

I. Introduction

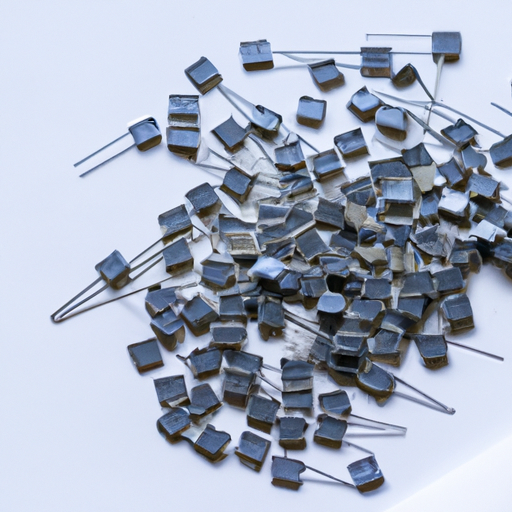

Stainless steel resistors are specialized electronic components that play a crucial role in controlling the flow of electric current in various circuits. These resistors are made from stainless steel, a material known for its durability and resistance to corrosion. In electronic circuits, resistors are essential for managing voltage and current levels, ensuring that devices operate safely and efficiently. This article aims to explore the different types of stainless steel resistors, their applications, advantages, and the future trends in this field.

II. Understanding Resistors

A. Basic Function of Resistors in Electrical Circuits

Resistors are passive electrical components that limit the flow of electric current. They are used to create specific voltage drops, divide voltages, and protect sensitive components from excessive current. By providing resistance, they help maintain the desired performance of electronic devices.

B. Types of Resistors

Resistors can be categorized into several types, including fixed resistors, variable resistors, and specialized resistors. Fixed resistors have a constant resistance value, while variable resistors, such as potentiometers, allow users to adjust the resistance as needed. Each type serves different purposes in electronic circuits.

C. Key Specifications

When selecting a resistor, several key specifications must be considered, including resistance value (measured in ohms), tolerance (the allowable deviation from the specified resistance), and power rating (the maximum power the resistor can dissipate without damage). These specifications are critical for ensuring that the resistor performs effectively in its intended application.

III. The Role of Material in Resistor Performance

A. Overview of Resistor Materials

Resistors can be made from various materials, including carbon, metal film, and wire wound. Each material has its unique properties that affect the resistor's performance, such as stability, accuracy, and temperature coefficient.

B. Advantages of Stainless Steel as a Resistor Material

Stainless steel offers several advantages as a resistor material:

1. **Corrosion Resistance**: Stainless steel is highly resistant to corrosion, making it suitable for use in harsh environments where moisture and chemicals are present.

2. **Durability and Longevity**: The robust nature of stainless steel ensures that resistors made from this material have a long lifespan, reducing the need for frequent replacements.

3. **Thermal Stability**: Stainless steel resistors maintain their performance across a wide range of temperatures, making them ideal for applications that experience temperature fluctuations.

C. Comparison with Other Materials

Compared to other resistor materials, stainless steel provides superior performance in terms of durability and resistance to environmental factors. While carbon resistors may be less expensive, they lack the longevity and stability that stainless steel offers. Metal film resistors, while precise, may not withstand extreme conditions as effectively as stainless steel.

IV. Types of Stainless Steel Resistors

A. Fixed Stainless Steel Resistors

Fixed stainless steel resistors have a predetermined resistance value and are widely used in various applications. They are commonly found in power supplies, amplifiers, and signal processing circuits. Typical resistance values range from a few ohms to several megaohms, with tolerances that can vary based on the application.

B. Variable Stainless Steel Resistors (Potentiometers)

Variable stainless steel resistors, or potentiometers, allow users to adjust resistance levels. These resistors are essential in applications such as volume controls in audio equipment and tuning circuits. They come in different types, including linear and logarithmic, each serving specific functions in electronic devices.

C. Wirewound Stainless Steel Resistors

Wirewound stainless steel resistors are constructed by winding a stainless steel wire around a ceramic or fiberglass core. This design allows for high power ratings and excellent thermal stability, making them suitable for high-power applications such as power supplies and motor controls.

D. Thin Film Stainless Steel Resistors

Thin film stainless steel resistors are manufactured by depositing a thin layer of stainless steel onto a substrate. This process results in resistors with high precision and low noise, making them ideal for use in precision electronics, such as medical devices and instrumentation.

E. Thick Film Stainless Steel Resistors

Thick film stainless steel resistors are produced by screen printing a thick layer of resistive material onto a substrate. These resistors are cost-effective and can be produced in various shapes and sizes, making them suitable for a wide range of applications across different industries.

V. Applications of Stainless Steel Resistors

A. Industrial Applications

Stainless steel resistors are widely used in industrial applications, including manufacturing and automation. They are essential in controlling motors, sensors, and other equipment, ensuring efficient operation in demanding environments.

B. Consumer Electronics

In consumer electronics, stainless steel resistors are found in home appliances, personal devices, and audio equipment. Their durability and reliability make them a preferred choice for manufacturers looking to produce long-lasting products.

C. Automotive Applications

In the automotive industry, stainless steel resistors are used in engine control units, safety systems, and various electronic components. Their ability to withstand harsh conditions, such as high temperatures and vibrations, makes them ideal for automotive applications.

D. Medical Devices

Stainless steel resistors play a critical role in medical devices, including diagnostic equipment and monitoring systems. Their precision and reliability are essential for ensuring accurate measurements and safe operation in healthcare settings.

VI. Advantages and Disadvantages of Stainless Steel Resistors

A. Advantages

1. **Resistance to Environmental Factors**: Stainless steel resistors can withstand moisture, chemicals, and extreme temperatures, making them suitable for various applications.

2. **High Reliability and Performance**: The durability and stability of stainless steel ensure consistent performance over time, reducing the risk of failure in critical applications.

B. Disadvantages

1. **Cost Considerations**: Stainless steel resistors can be more expensive than their carbon or metal film counterparts, which may limit their use in cost-sensitive applications.

2. **Limited Availability in Certain Specifications**: While stainless steel resistors are versatile, they may not be available in all resistance values or tolerances, which could restrict their use in specific applications.

VII. Future Trends in Stainless Steel Resistors

A. Innovations in Materials and Manufacturing Processes

As technology advances, new materials and manufacturing processes are being developed to enhance the performance of stainless steel resistors. Innovations such as improved coating techniques and advanced fabrication methods are expected to lead to even more reliable and efficient resistors.

B. Increasing Demand in Various Sectors

The demand for stainless steel resistors is expected to grow across various sectors, including industrial automation, consumer electronics, and automotive applications. As industries continue to prioritize durability and reliability, stainless steel resistors will play a vital role in meeting these needs.

C. Potential for New Applications and Technologies

With the rise of new technologies, such as electric vehicles and renewable energy systems, the potential applications for stainless steel resistors are expanding. Their unique properties make them well-suited for emerging technologies that require high performance and reliability.

VIII. Conclusion

Stainless steel resistors are essential components in modern electronic circuits, offering durability, reliability, and resistance to environmental factors. This article has explored the various types of stainless steel resistors, their applications, advantages, and potential future trends. As technology continues to evolve, stainless steel resistors will remain a critical element in ensuring the performance and longevity of electronic devices.

IX. References

1. "Resistor Types and Their Applications," Electronics Tutorials.

2. "The Role of Resistors in Electronic Circuits," IEEE Xplore.

3. "Material Properties of Stainless Steel Resistors," Journal of Electronic Materials.

4. "Advancements in Resistor Technology," Electronics Weekly.

5. "Stainless Steel in Electronics: A Comprehensive Guide," Materials Science Journal.