What are the latest resistors? What are the purchasing models of equipment components?

What are the Latest Resistors? What are the Purchasing Models of Equipment Components?

I. Introduction

Resistors are fundamental components in electronic circuits, serving the essential function of limiting current flow and dividing voltages. They play a critical role in ensuring that electronic devices operate correctly and efficiently. As technology evolves, so do the materials and designs of resistors, making it crucial for engineers and hobbyists alike to stay updated with the latest advancements. This blog post will explore the latest developments in resistor technology and examine the various purchasing models for equipment components, providing insights into how to make informed decisions in this rapidly changing landscape.

II. Overview of Resistor Technology

A. Historical Context of Resistors

The history of resistors dates back to the early days of electricity. Initially, resistors were made from simple materials like carbon and wire. Over the years, advancements in materials science and manufacturing processes have led to the development of various types of resistors, each designed for specific applications and performance requirements.

B. Types of Resistors

1. **Fixed Resistors**: These resistors have a constant resistance value and are the most commonly used type. They are available in various materials, including carbon, metal, and wire-wound.

2. **Variable Resistors (Potentiometers)**: These allow users to adjust the resistance value manually. They are often used in applications like volume controls and tuning circuits.

3. **Specialty Resistors**: This category includes thermistors, which change resistance with temperature, and photoresistors, which vary resistance based on light exposure. These resistors are crucial in applications requiring sensitivity to environmental changes.

C. Key Specifications and Parameters

When selecting resistors, several key specifications must be considered:

1. **Resistance Value**: Measured in ohms, this indicates how much the resistor opposes current flow.

2. **Tolerance**: This specification indicates how much the actual resistance can vary from the stated value, typically expressed as a percentage.

3. **Power Rating**: Measured in watts, this indicates the maximum power the resistor can dissipate without being damaged.

4. **Temperature Coefficient**: This parameter indicates how much the resistance changes with temperature, which is critical for applications requiring stability across varying temperatures.

III. Latest Developments in Resistor Technology

A. Advances in Materials

Recent advancements in materials have significantly improved resistor performance.

1. **Carbon Film Resistors**: These resistors offer better stability and lower noise compared to traditional carbon composition resistors. They are widely used in precision applications.

2. **Metal Film Resistors**: Known for their high accuracy and low temperature coefficient, metal film resistors are ideal for applications requiring precise resistance values.

3. **Thin-Film and Thick-Film Technologies**: These technologies allow for the production of resistors with very small dimensions, making them suitable for modern compact electronic devices.

B. Innovations in Design

The design of resistors has also evolved, with several innovations enhancing their functionality.

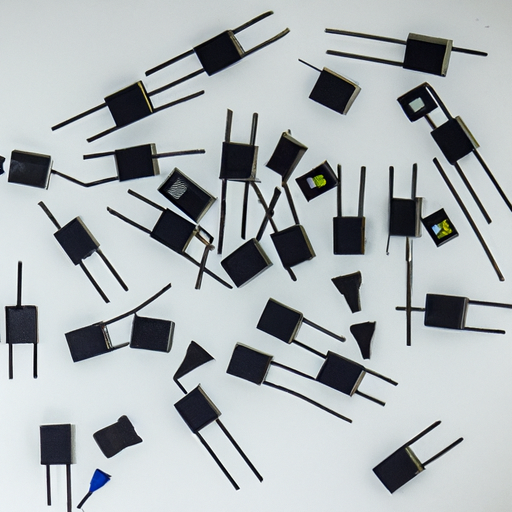

1. **Surface Mount Technology (SMT) Resistors**: SMT resistors are designed for automated assembly processes, allowing for smaller and more efficient circuit designs.

2. **Chip Resistors**: These resistors are compact and can be easily integrated into circuit boards, making them ideal for high-density applications.

3. **High-Precision Resistors**: These resistors are designed for applications requiring extremely accurate resistance values, such as in instrumentation and measurement devices.

C. Emerging Trends

Several emerging trends are shaping the future of resistor technology.

1. **Miniaturization and Integration**: As electronic devices become smaller, the demand for miniaturized components, including resistors, continues to grow. This trend is driving innovation in resistor design and manufacturing.

2. **Smart Resistors and IoT Applications**: With the rise of the Internet of Things (IoT), there is a growing need for smart resistors that can communicate data and adapt to changing conditions.

3. **Environmental Considerations and Sustainability**: Manufacturers are increasingly focusing on sustainable practices, including the use of eco-friendly materials and processes in resistor production.

IV. Applications of Modern Resistors

Modern resistors find applications across various industries, reflecting their versatility and importance.

A. Consumer Electronics

In consumer electronics, resistors are used in everything from smartphones to televisions, ensuring proper functionality and performance.

B. Automotive Industry

Resistors play a critical role in automotive applications, including engine control units, safety systems, and infotainment systems, where reliability and precision are paramount.

C. Industrial Automation

In industrial settings, resistors are used in control systems, sensors, and automation equipment, contributing to efficiency and safety.

D. Telecommunications

Telecommunications equipment relies on resistors for signal processing and transmission, ensuring clear and reliable communication.

E. Medical Devices

In the medical field, precision resistors are essential for devices such as diagnostic equipment and monitoring systems, where accuracy can be a matter of life and death.

V. Purchasing Models for Equipment Components

A. Overview of Purchasing Models

When it comes to acquiring resistors and other equipment components, several purchasing models are available:

1. **Direct Purchasing**: This model involves buying components directly from manufacturers, often resulting in lower costs but requiring more effort in terms of sourcing and logistics.

2. **Distributor Partnerships**: Many companies choose to work with distributors who can provide a wide range of components, simplifying the purchasing process and offering additional services like technical support.

3. **Online Marketplaces**: The rise of e-commerce has led to the emergence of online marketplaces where buyers can easily compare prices and specifications from various suppliers.

B. Factors Influencing Purchasing Decisions

Several factors influence the decision-making process when purchasing resistors:

1. **Cost Considerations**: Price is often a primary factor, but it should be balanced with quality and reliability.

2. **Quality and Reliability**: Ensuring that components meet industry standards and specifications is crucial for maintaining product performance.

3. **Lead Times and Availability**: The ability to obtain components quickly can be a significant factor, especially in industries with tight deadlines.

4. **Technical Support and Service**: Access to knowledgeable support can be invaluable, particularly for complex projects requiring specific resistor types.

C. Evaluating Suppliers

When selecting suppliers, several criteria should be considered:

1. **Supplier Reputation and History**: Researching a supplier's track record can provide insights into their reliability and quality.

2. **Certifications and Compliance**: Ensuring that suppliers meet industry standards and regulations is essential for maintaining product integrity.

3. **Customer Reviews and Feedback**: Reading reviews and testimonials from other customers can help gauge a supplier's performance and service quality.

VI. Conclusion

Understanding the latest developments in resistor technology is essential for anyone involved in electronics, from engineers to hobbyists. As technology continues to advance, staying informed about new materials, designs, and applications will help ensure that projects are successful and efficient. Additionally, being aware of the various purchasing models and factors influencing decisions can lead to more informed choices when acquiring equipment components. The future of resistors and equipment components in the electronics industry looks promising, with ongoing innovations and a focus on sustainability paving the way for even more exciting developments.

VII. References

1. Academic journals and articles on resistor technology and materials science.

2. Industry reports and white papers discussing trends in electronics and component purchasing.

3. Manufacturer websites and product catalogs for the latest resistor offerings and specifications.

This comprehensive overview of resistors and purchasing models provides a solid foundation for understanding the current landscape and future directions in the electronics industry.