Form: :

2024-05-18 14:43:53

0

Linear integrated circuit is an integrated circuit based on amplifier. The word "linear" means that the response of the amplifier to the input signal usually presents a linear relationship. Later, this kind of circuit includes many nonlinear circuits such as oscillator, timer and data converter, as well as the circuit combining digital and linear functions. Because the information processed involves continuously changing physical quantities (analog quantities), people also call this kind of circuit analog integrated circuit.

A new development in linear circuits is the use of MOS technology to manufacture audio filters. Its principle is switched capacitor method, that is, the capacitor is alternately connected to different voltage nodes in the circuit with a switch to transmit charges, so as to produce equivalent resistance. This technology is especially suitable for MOS process (see switched capacitor filter). On the other hand, due to the application of analog sampling technology, MOS technology has been able to produce high stability operational amplifiers and high-precision digital to analog and analog to digital converters. The combination of these two technologies opens up a broad prospect for the large-scale integration technology of analog information processing and communication equipment subsystems.

In terms of manufacturing process, most linear integrated circuits are manufactured by standard bipolar process. In order to obtain high-performance circuits, some modifications or additional manufacturing processes are sometimes made on the basis of standard processes, so as to make various components and devices with different performances on the same chip.

According to the functions and applications of circuits, linear integrated circuits can be roughly divided into:

General circuit, including operational amplifier, voltage comparator, voltage reference circuit and regulated power supply circuit;

Industrial control and measurement circuit, including timer, waveform generator, detector, sensor circuit, phase-locked loop, analog multiplier, motor drive circuit, power control circuit, analog switch;

Data conversion circuit, including digital to analog converter, analog to digital converter, voltage frequency converter;

Communication circuit, including telephone communication circuit and mobile communication circuit;

Consumer circuits, including television circuits, video recorder circuits, and audio circuits. In fact, there are many other circuits, such as medical circuits such as cardiac pacemakers.

On the other hand, due to the increasing development of large-scale integration technology and computer-aided design and measurement technology, the design of linear circuits is developing from traditional standard units to custom integrated circuits with complex functions.

Form: :

2024-05-17 14:13:45

0

Field programmable gate array (FPGA) is the product of further development on the basis of programmable devices such as pal (programmable array logic) and gal (general array logic). As a semi custom circuit in the field of application specific integrated circuits (ASIC), it not only solves the shortcomings of custom circuits, but also overcomes the shortcomings of the limited number of programmable devices.

The mainstream manufacturers of field programmable gate array FPGA chips include Xilinx, Altera, lattice and MICROSEMI, of which the first two have a total market share of 88%.

Field programmable gate array FPGA is a semiconductor device composed of configurable logic block (CLB) matrix connected through programmable interconnection. FPGA can be reprogrammed according to the required application or functional requirements after manufacturing.

This feature is the key to the difference between FPGA and ASIC. You can customize FPGA devices for specific design tasks. Although there are also one-time programmable (OTP) FPGAs on the market, most of them are based on SRAM and can be reprogrammed as the design evolves.

Field programmable gate array FPGA has a very mature and wide range of applications in the aerospace, military, telecommunications fields. Taking the telecommunication field as an example, in the stage of all-in-one telecommunication equipment, FPGA is applied to network protocol parsing and interface conversion because of its programming flexibility and high performance. In the nfv scenario, FPGA based on the general server and hypervisor can achieve a 5-fold performance improvement of the network element data plane, and can be managed and arranged by the openstack cyborg hardware acceleration framework.

In terms of chip design, we need to focus on rationality in algorithm design to ensure the final completion effect of the project, and put forward a solution to the problem according to the actual situation of the project, so as to improve the operation efficiency of FPGA. After the algorithm is determined, the module should be constructed reasonably to facilitate the later code design.

In the code design, we can use the pre designed code to improve work efficiency and reliability. Write the test platform, carry out the code simulation test and board debugging, and complete the whole design process. Unlike ASIC, FPGA has a short development cycle. It can change the hardware structure in combination with the design requirements. When the communication protocol is immature, it can help enterprises quickly launch new products and meet the needs of non-standard interface development.

Form: :

1970-01-01 08:00:00

0

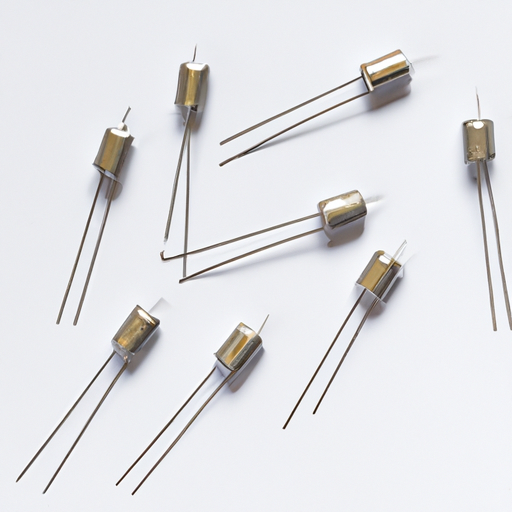

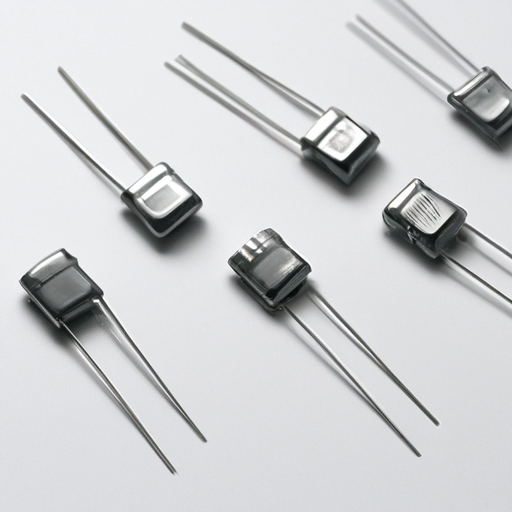

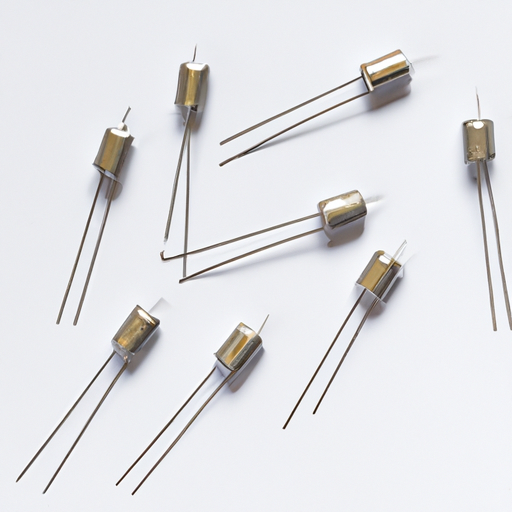

Crystal oscillators can help electronic systems provide frequencies for synchronous operation, as frequency references or to achieve accurate timing.

In microprocessor-based systems, there are several different frequency signals used to execute instructions, move data into and out of memory, and external communication interfaces.

A simple embedded controller may have a clock frequency of several MHz, while microprocessors in personal computers usually expect an input frequency of 15 MHz. This will multiply internally to provide the frequency of the CPU and other subsystems. Other components in the system may have their own frequency requirements.

In addition to providing the basic requirements of the specified frequency, the oscillator may have to meet other requirements depending on the application requirements of the product.

For example, many product applications require extremely precisely defined frequencies. This is particularly important for systems that need to communicate with other devices through serial or wireless interfaces. Accuracy is usually measured in parts per million (PPM).

At the same time, the trimming circuit can be based on resistance capacitance (RC) or inductance capacitance (LC) networks. These devices are relatively simple and can change the frequency in a wide range. However, designing an accurate RC oscillator or LC oscillator requires the use of expensive precise components. Even so, they cannot meet the highest accuracy and stability required by many product applications.

Crystal oscillators (usually quartz) can also be used as resonant components. Cut the crystal into two parallel crystal planes and deposit metal contacts on them. Quartz has piezoelectric effect, which means that when the crystal is placed under pressure, voltage will be generated on its crystal surface. On the contrary, when voltage is applied to the crystal, the crystal will also change its shape.

Form: :

1970-01-01 08:00:00

0

Digital potentiometer, also known as numerical control device, is a new type of CMOS integrated circuit for mixed digital and analog signal processing. The digital potentiometer is controlled by digital input and generates analog output.

According to different digital potentiometers, the maximum tap current can range from hundreds of microamps to several milliamps. The digital potentiometer adopts numerical control to adjust the resistance value, which has the remarkable advantages of flexibility, high adjustment accuracy, no contact, low noise, not easy to damage, anti vibration, anti-interference, small size, long service life and so on. It can replace the mechanical potentiometer in many fields.

Potentiometer is an adjustable electronic component. It is composed of a resistor and a rotating or sliding system. When a voltage is applied between the two fixed contacts of the resistance body, the position of the contact on the resistance body is changed by rotating or sliding system, and a voltage that is certain to the position of the moving contact can be obtained between the moving contact and the fixed contact.

Potentiometer is a resistance element with three leads, and the resistance value can be adjusted according to a certain change law. Potentiometers usually consist of resistors and movable brushes. When the brush moves along the resistance body, the resistance value or voltage that is related to the displacement is obtained at the output end.

The potentiometer can be used as either a three terminal element or a two terminal element. The latter can be regarded as a variable resistor. Because its function in the circuit is to obtain an output voltage that is related to the input voltage (applied voltage), it is called a potentiometer.

In terms of application scope, digital potentiometers are rapidly promoted at home and abroad, and are widely used in detection instruments, PCs, mobile phones, household appliances, modern office equipment, industrial control, medical equipment and other fields. For example: refrigerator, programmable computer, power supply, power meter, automatic detection equipment, optical fiber network, adjusting LCD display, voltage control, replacing mechanical potentiometer, matching linear impedance, adjusting VCOM settings.

Form: :

2024-05-14 17:35:45

0

Common mode chokes, also known as common mode inductors, are coils symmetrically wound on a closed magnetic ring in opposite directions and with the same number of turns. It is often used to filter common mode electromagnetic interference, suppress the outward radiation and emission of electromagnetic waves generated by high-speed signal lines, and improve the EMC of the system. In practical applications, it is generally to add common mode inductance to the differential signal line.

Signal interference is mainly divided into common mode interference and differential mode interference.

There are two forms of voltage and current changes when they are transmitted through wires, which we call "common mode" and "differential mode". In addition to these two wires, there is usually a third conductor, which is "ground". There are two kinds of interference voltage and current: one is that two wires are used as round-trip lines respectively; The other is that two wires are used as the going path and the ground wire is used as the return path. The former is called "differential mode" and the latter is called "common mode".

Usually, the electrical appliances we use are two-wire, a live wire [2] (L) and a zero wire (n). The zero wire is considered as the neutral line of three-phase electricity, and there is also a ground wire called ground wire. The interference between zero line and live line is called differential mode interference, and the interference between live line and ground line is called common mode interference.

Usually, on the line, the differential mode component and common mode component of the interference voltage exist at the same time, and because of the imbalance of the line impedance, the two components will transform into each other in transmission.

Then, how does the common mode choke solve the problem of common mode interference?

The principle of common mode inductance suppressing common mode interference is also very simple. According to the right-hand screw rule, when two coils with the same magnetic ring winding in the opposite direction pass through two voltages with the same polarity and equal amplitude, the magnetic flux generated is superimposed with each other, and the inductive reactance is: xl=wl, which is very large. The magnetic flux generated by the differential signal cancels each other.

Form: :

2024-03-25 04:18:07

1

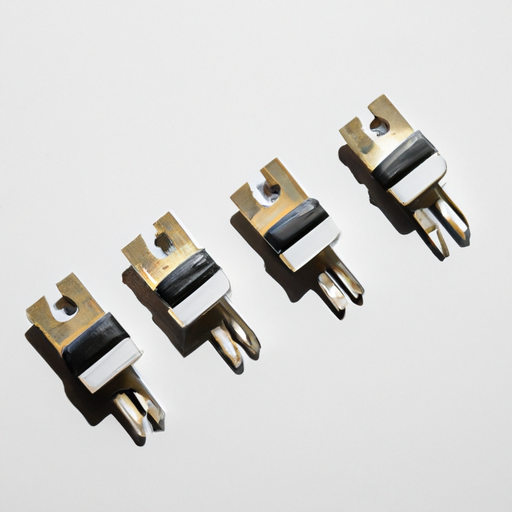

Fixed resistors are electronic components that are used to limit the flow of electric current in a circuit. They are designed to have a specific resistance value that remains constant, hence the name "fixed resistor". These components are essential in various electronic devices and systems, as they help control the flow of electricity and protect other components from damage.In order to ensure the quality and reliability of fixed resistors, there are certain product standards that manufacturers must adhere to. These standards are put in place to guarantee that the resistors meet certain criteria for performance, safety, and durability. In this article, we will discuss the product standards for fixed resistors and why they are important.One of the most important product standards for fixed resistors is the resistance tolerance. This refers to the allowable deviation from the specified resistance value. For example, a resistor with a resistance value of 100 ohms and a tolerance of ±5% means that the actual resistance of the resistor can be anywhere between 95 ohms and 105 ohms. The tighter the tolerance, the more precise the resistor is in terms of its resistance value. Common tolerance values for fixed resistors include ±1%, ±5%, and ±10%.Another important product standard for fixed resistors is the power rating. This indicates the maximum amount of power that the resistor can safely dissipate without overheating or failing. The power rating is typically measured in watts and is determined by factors such as the resistor's size, construction, and material. It is important to select a resistor with a power rating that is suitable for the application to prevent damage or failure.In addition to resistance tolerance and power rating, fixed resistors must also meet certain standards for temperature coefficient, voltage rating, and reliability. The temperature coefficient specifies how the resistance of the resistor changes with temperature, while the voltage rating indicates the maximum voltage that the resistor can withstand without breaking down. Reliability standards ensure that the resistor will perform consistently over its expected lifespan without premature failure.One of the most widely recognized product standards for fixed resistors is the International Electrotechnical Commission (IEC) 60062 standard. This standard defines the color coding system used to indicate the resistance value, tolerance, and temperature coefficient of fixed resistors. The color bands on the resistor's body provide a quick and easy way to identify these parameters without the need for additional testing or measurement.In addition to the IEC standard, fixed resistors may also be subject to other industry-specific standards such as those set by the Institute of Electrical and Electronics Engineers (IEEE) or the Electronic Industries Alliance (EIA). These standards help ensure that fixed resistors are compatible with other components and systems, and that they meet the requirements of specific applications or industries.Overall, product standards for fixed resistors are essential for ensuring the quality, performance, and reliability of these electronic components. By adhering to these standards, manufacturers can produce resistors that meet the needs of their customers and perform consistently in a wide range of applications. Whether used in consumer electronics, industrial equipment, or automotive systems, fixed resistors play a crucial role in controlling the flow of electricity and maintaining the integrity of electronic circuits.

Form: :

2024-03-24 04:18:10

1

Color ring resistors are a type of resistor that is commonly used in electronic circuits to limit the flow of electric current. They are called color ring resistors because they have colored bands on their body that indicate their resistance value. These resistors are available in a wide range of resistance values and power ratings, making them suitable for a variety of applications.One of the key features of color ring resistors is their accuracy. The colored bands on the body of the resistor are used to determine its resistance value. Each color represents a specific digit, and by reading the colors from left to right, you can determine the resistance value of the resistor. This makes it easy to identify the resistance value of the resistor without the need for additional tools or equipment.Another important feature of color ring resistors is their reliability. These resistors are made from high-quality materials that are designed to withstand high temperatures and harsh operating conditions. This makes them suitable for use in a wide range of applications, including industrial and automotive electronics.Color ring resistors are also known for their stability. They have a low temperature coefficient, which means that their resistance value remains relatively constant over a wide range of temperatures. This makes them ideal for use in circuits that are exposed to varying temperatures, as they will not drift or change their resistance value significantly.In addition to their accuracy, reliability, and stability, color ring resistors also offer a high power rating. This means that they can handle high levels of current without overheating or failing. This makes them suitable for use in circuits that require high power handling capabilities, such as power supplies and amplifiers.Color ring resistors are also available in a variety of package sizes and configurations, making them easy to integrate into different types of circuits. They are typically available in axial lead packages, which are easy to solder onto circuit boards. They are also available in surface mount packages, which are ideal for use in compact electronic devices.Overall, color ring resistors are a versatile and reliable component that is essential for many electronic circuits. Their accuracy, reliability, stability, and high power rating make them suitable for a wide range of applications. Whether you are building a simple LED circuit or a complex audio amplifier, color ring resistors are an essential component that you can rely on to provide accurate and consistent performance.

Form: :

2024-03-23 04:18:05

1

Brake resistors are an essential component in many industrial applications where braking of motors is required. They are used to dissipate the excess energy generated during the braking process, preventing damage to the motor and ensuring smooth operation of the machinery. In this article, we will explore the various product features of brake resistors and their importance in different industries.1. High Power Dissipation Capacity: One of the key features of brake resistors is their ability to dissipate high amounts of power. This is crucial in applications where the motor generates a significant amount of energy during braking, which needs to be safely dissipated to prevent overheating and damage to the motor. Brake resistors are designed to handle this excess energy efficiently, ensuring the smooth operation of the machinery.2. Compact and Space-saving Design: Brake resistors are typically compact in size, making them ideal for installations where space is limited. Their small footprint allows for easy integration into existing systems without taking up too much space. This feature is particularly important in industries where space is a premium, such as in manufacturing plants and industrial facilities.3. High Temperature Resistance: Brake resistors are designed to withstand high temperatures generated during braking. They are made from high-quality materials that can withstand the heat generated during the dissipation of energy. This ensures the longevity and durability of the resistor, even in harsh operating conditions.4. Fast Response Time: Brake resistors have a fast response time, allowing them to quickly dissipate the excess energy generated during braking. This ensures that the motor is protected from damage and that the machinery operates smoothly without any interruptions. The fast response time of brake resistors is crucial in applications where quick braking is required, such as in emergency stop situations.5. Easy Installation and Maintenance: Brake resistors are designed for easy installation and maintenance. They can be easily integrated into existing systems without the need for extensive modifications. Additionally, they require minimal maintenance, reducing downtime and ensuring the continuous operation of the machinery.6. Wide Range of Power Ratings: Brake resistors are available in a wide range of power ratings to suit different applications. Whether you need a small resistor for a low-power motor or a high-power resistor for a heavy-duty industrial application, there is a brake resistor available to meet your specific requirements. This versatility makes brake resistors suitable for a wide range of industries and applications.7. Cost-effective Solution: Brake resistors are a cost-effective solution for braking applications. They are relatively inexpensive compared to other braking systems and require minimal maintenance, reducing overall operating costs. Additionally, their high efficiency and reliability ensure that the machinery operates smoothly, reducing the risk of costly downtime and repairs.In conclusion, brake resistors are an essential component in many industrial applications where braking of motors is required. Their high power dissipation capacity, compact design, high temperature resistance, fast response time, easy installation and maintenance, wide range of power ratings, and cost-effective nature make them a popular choice for a wide range of industries. Whether you need to brake a small motor or a heavy-duty industrial machine, brake resistors are a reliable and efficient solution to ensure the smooth operation of your machinery.

Form: :

2024-03-22 04:10:10

0

The release of a new standard resistor is a significant event in the world of electronics and engineering. Standard resistors are essential components in a wide range of electronic devices and systems, providing a known and stable resistance value for use in calibration, testing, and measurement applications. The development and release of a new standard resistor can have a major impact on industries such as telecommunications, aerospace, automotive, and more.The release of a new standard resistor is typically a carefully planned and coordinated effort involving manufacturers, standards organizations, and regulatory bodies. The process of developing a new standard resistor begins with the identification of a need for a new or updated standard, often driven by advances in technology or changes in industry requirements. Once the need has been identified, a working group or committee is formed to develop the new standard, taking into account factors such as resistance value, tolerance, temperature coefficient, and stability.The development of a new standard resistor can take several months or even years, depending on the complexity of the requirements and the level of consensus among stakeholders. Once the new standard has been finalized, it must undergo a rigorous testing and validation process to ensure that it meets the necessary performance criteria and can be reliably used in a wide range of applications. This testing process may involve comparison with existing standards, calibration against known reference values, and evaluation of long-term stability and reliability.Once the new standard resistor has been successfully validated, it is typically published by a recognized standards organization such as the International Electrotechnical Commission (IEC) or the American National Standards Institute (ANSI). The publication of a new standard resistor is often accompanied by a press release or announcement to inform the industry of its availability and significance. Manufacturers may also begin production of the new standard resistor, making it available for purchase by customers and users.The release of a new standard resistor can have a number of benefits for the industry and for end users. For manufacturers, the availability of a new standard resistor can open up new markets and opportunities for product development. For users, the adoption of a new standard resistor can improve the accuracy and reliability of their measurements and testing procedures, leading to better overall performance and quality in their products and systems.In conclusion, the release of a new standard resistor is a significant event in the world of electronics and engineering, with implications for a wide range of industries and applications. The development and release of a new standard resistor involves a careful and thorough process of testing, validation, and publication, ultimately leading to improved performance and reliability for users. The release of a new standard resistor is an important milestone in the ongoing advancement of technology and innovation in the field of electronics.

Form: :

2024-03-21 04:18:05

0

Pressure-sensitive resistors, also known as force-sensitive resistors or force-sensing resistors, are a type of sensor that changes its resistance based on the amount of pressure or force applied to it. These sensors are widely used in various industries for applications such as touch screens, medical devices, automotive systems, robotics, and more. As a result, there are important patents related to pressure-sensitive resistors in several key industries.One industry that contains important patents related to pressure-sensitive resistors is the consumer electronics industry. With the rise of touch screen technology in smartphones, tablets, and other devices, pressure-sensitive resistors have become essential components in these products. Companies like Apple, Samsung, and Google have filed patents for innovative touch screen technologies that incorporate pressure-sensitive resistors to improve the user experience. These patents cover aspects such as multi-touch functionality, pressure sensitivity levels, and gesture recognition, all of which rely on the accurate and reliable performance of pressure-sensitive resistors.Another industry that relies heavily on pressure-sensitive resistors is the automotive industry. Pressure-sensitive resistors are used in various automotive applications, such as airbag systems, seat occupancy sensors, and brake pedal sensors. These sensors play a crucial role in ensuring the safety and functionality of modern vehicles. Companies like Bosch, Continental, and Delphi have patented technologies that utilize pressure-sensitive resistors to improve the performance and reliability of these automotive systems. These patents cover areas such as crash detection algorithms, seat belt tensioning systems, and adaptive cruise control systems, all of which rely on the accurate measurement of pressure using pressure-sensitive resistors.The medical industry is another important sector that contains patents related to pressure-sensitive resistors. Pressure-sensitive resistors are used in medical devices such as blood pressure monitors, respiratory therapy devices, and prosthetic limbs. These sensors help healthcare professionals monitor and control various physiological parameters in patients, leading to better diagnosis and treatment outcomes. Companies like Medtronic, Philips, and Johnson & Johnson have patented technologies that incorporate pressure-sensitive resistors to improve the accuracy and reliability of these medical devices. These patents cover areas such as remote patient monitoring systems, drug delivery devices, and surgical instruments, all of which rely on the precise measurement of pressure using pressure-sensitive resistors.The robotics industry is also a key sector that relies on pressure-sensitive resistors for various applications. Pressure-sensitive resistors are used in robotic grippers, tactile sensors, and force feedback systems to enable robots to interact with their environment and perform tasks with precision. Companies like ABB, Fanuc, and KUKA have patented technologies that utilize pressure-sensitive resistors to improve the dexterity and sensitivity of robotic systems. These patents cover areas such as object recognition algorithms, force control mechanisms, and haptic feedback systems, all of which rely on the accurate measurement of pressure using pressure-sensitive resistors.In conclusion, pressure-sensitive resistors are essential components in a wide range of industries, including consumer electronics, automotive, medical, and robotics. Companies in these industries have filed important patents related to pressure-sensitive resistors to protect their innovative technologies and stay ahead of the competition. These patents cover various aspects of pressure-sensitive resistor technology, from touch screen functionality to automotive safety systems to medical devices and robotic applications. As the demand for pressure-sensitive resistors continues to grow, we can expect to see more groundbreaking inventions and patents in the future, further advancing the capabilities and applications of these versatile sensors.